Smelting Crucibles fun Aluminiomu ajeku ati aluminiomu ingot

Ọja ẸYA

Superior Gbona Conductivity

Iparapọ alailẹgbẹ ti ohun alumọni carbide ati lẹẹdi ṣe idaniloju iyara ati alapapo aṣọ, gige ni pataki ni akoko yo.

Awọn iwọn otutu Resistance

Iparapọ alailẹgbẹ ti ohun alumọni carbide ati lẹẹdi ṣe idaniloju iyara ati alapapo aṣọ, gige ni pataki ni akoko yo.

Ti o tọ Ipata Resistance

Iparapọ alailẹgbẹ ti ohun alumọni carbide ati lẹẹdi ṣe idaniloju iyara ati alapapo aṣọ, gige ni pataki ni akoko yo.

Awọn alaye imọ-ẹrọ

| No | Awoṣe | OD | H | ID | BD |

| 1 | 80 | 330 | 410 | 265 | 230 |

| 2 | 100 | 350 | 440 | 282 | 240 |

| 3 | 110 | 330 | 380 | 260 | 205 |

| 4 | 200 | 420 | 500 | 350 | 230 |

| 5 | 201 | 430 | 500 | 350 | 230 |

| 6 | 350 | 430 | 570 | 365 | 230 |

| 7 | 351 | 430 | 670 | 360 | 230 |

| 8 | 300 | 450 | 500 | 360 | 230 |

| 9 | 330 | 450 | 450 | 380 | 230 |

| 10 | 350 | 470 | 650 | 390 | 320 |

| 11 | 360 | 530 | 530 | 460 | 300 |

| 12 | 370 | 530 | 570 | 460 | 300 |

| 13 | 400 | 530 | 750 | 446 | 330 |

| 14 | 450 | 520 | 600 | 440 | 260 |

| 15 | 453 | 520 | 660 | 450 | 310 |

| 16 | 460 | 565 | 600 | 500 | 310 |

| 17 | 463 | 570 | 620 | 500 | 310 |

| 18 | 500 | 520 | 650 | 450 | 360 |

| 19 | 501 | 520 | 700 | 460 | 310 |

| 20 | 505 | 520 | 780 | 460 | 310 |

| 21 | 511 | 550 | 660 | 460 | 320 |

| 22 | 650 | 550 | 800 | 480 | 330 |

| 23 | 700 | 600 | 500 | 550 | 295 |

| 24 | 760 | 615 | 620 | 550 | 295 |

| 25 | 765 | 615 | 640 | 540 | 330 |

| 26 | 790 | 640 | 650 | 550 | 330 |

| 27 | 791 | 645 | 650 | 550 | 315 |

| 28 | 801 | 610 | 675 | 525 | 330 |

| 29 | 802 | 610 | 700 | 525 | 330 |

| 30 | 803 | 610 | 800 | 535 | 330 |

| 31 | 810 | 620 | 830 | 540 | 330 |

| 32 | 820 | 700 | 520 | 597 | 280 |

| 33 | 910 | 710 | 600 | 610 | 300 |

| 34 | 980 | 715 | 660 | 610 | 300 |

| 35 | 1000 | 715 | 700 | 610 | 300 |

Sisan ilana

1. konge agbekalẹ

Lẹẹdi mimọ-giga + ohun alumọni carbide Ere + aṣoju abuda ohun-ini.

.

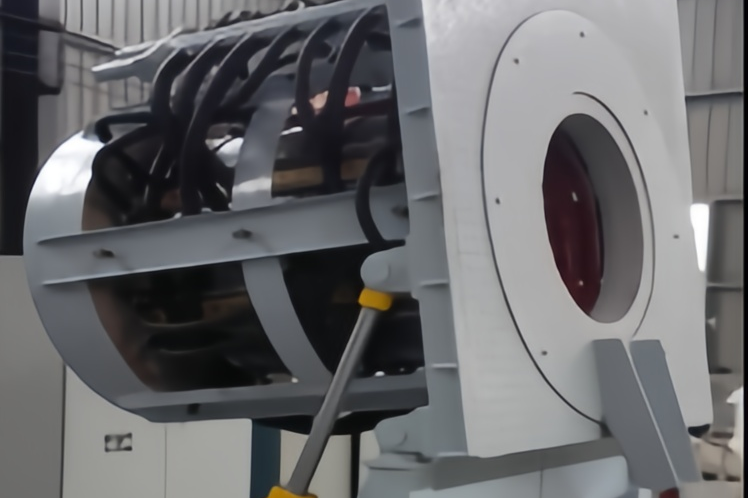

2.Isostatic Titẹ

Ìwọ̀n tó 2.2g/cm³ | Ifarada sisanra odi ± 0.3m

.

3.High-Temperature Sintering

SiC patiku recrystallization lara 3D nẹtiwọki be

.

4. Dada Imudara

Anti-oxidation bo → 3× ilọsiwaju ipata resistance

.

5.Ayẹwo Didara lile

Koodu ipasẹ alailẹgbẹ fun wiwa wiwa igbesi aye ni kikun

.

6.Iṣakojọpọ aabo

mọnamọna-absorbent Layer + Ọrinrin idankan + Fikun casing

.

Ọja elo

Gaasi yo ileru

Ifibọ yo ileru

Resistance Yo ileru

IDI TI O FI YAN WA

FAQS

Q1: Kini awọn anfani ti ohun alumọni carbide graphite crucibles ti a fiwe si awọn ohun elo graphite ibile?

✅Ti o ga otutu Resistance: Le withstand 1800 ° C gun-igba ati 2200 ° C kukuru-igba (vs. ≤1600 ° C fun lẹẹdi).

✅Igbesi aye gigun: 5x dara gbona mọnamọna resistance, 3-5x gun apapọ iṣẹ aye.

✅Odo Kokoro: Ko si erogba ilaluja, aridaju didà irin ti nw.

Q2: Awọn irin wo ni o le yo ninu awọn crucibles wọnyi?

▸Awọn irin ti o wọpọ: Aluminiomu, Ejò, sinkii, wura, fadaka, ati be be lo.

▸Awọn irin ifaseyinLitiumu, iṣuu soda, kalisiomu (nilo Si₃N₄ ti a bo).

▸Awọn irin Refractory: Tungsten, molybdenum, titanium (nbeere igbale / gaasi iner).

Q3: Ṣe awọn crucibles tuntun nilo itọju iṣaaju ṣaaju lilo?

Dandan yan: Laiyara ooru si 300 ° C → diduro fun wakati 2 (yokuro ọrinrin ti o ku).

First Yo Iṣeduro: Yo a ipele ti alokuirin ohun elo akọkọ (fọọmu kan aabo Layer).

Q4: Bawo ni a ṣe le ṣe idiwọ gbigbọn crucible?

Maṣe gba agbara ohun elo tutu sinu ibi isunmọ gbona (max ΔT <400°C).

Oṣuwọn itutu lẹhin yo <200 ° C / wakati.

Lo awọn tongs crucible igbẹhin (yago fun ipa ẹrọ).

Q5: Bawo ni lati dena crucible wo inu?

Maṣe gba agbara ohun elo tutu sinu ibi isunmọ gbona (max ΔT <400°C).

Oṣuwọn itutu lẹhin yo <200 ° C / wakati.

Lo awọn tongs crucible igbẹhin (yago fun ipa ẹrọ).

Q6: Kini opoiye aṣẹ ti o kere julọ (MOQ)?

Standard Models: 1 nkan (awọn ayẹwo ti o wa).

Awọn aṣa aṣa: 10 ege (CAD yiya beere).

Q7: Kini akoko asiwaju?

⏳Ni-Iṣura Awọn ohun: Ọkọ laarin 48 wakati.

⏳Awọn aṣẹ aṣa: 15-25awọn ọjọfun isejade ati 20 ọjọ fun m.

Q8: Bawo ni a ṣe le pinnu boya crucible kan ti kuna?

Awọn dojuijako> 5mm lori ogiri inu.

Ijinle ilaluja irin> 2mm.

Idibajẹ> 3% (wọn iyipada iwọn ila opin ita).

Q9: Ṣe o pese itọnisọna ilana yo?

Alapapo ekoro fun orisirisi awọn irin.

Ẹrọ iṣiro oṣuwọn sisan gaasi inert.

Slag yiyọ fidio Tutorial.